Stator core &

end-winding vibrations

Stator core

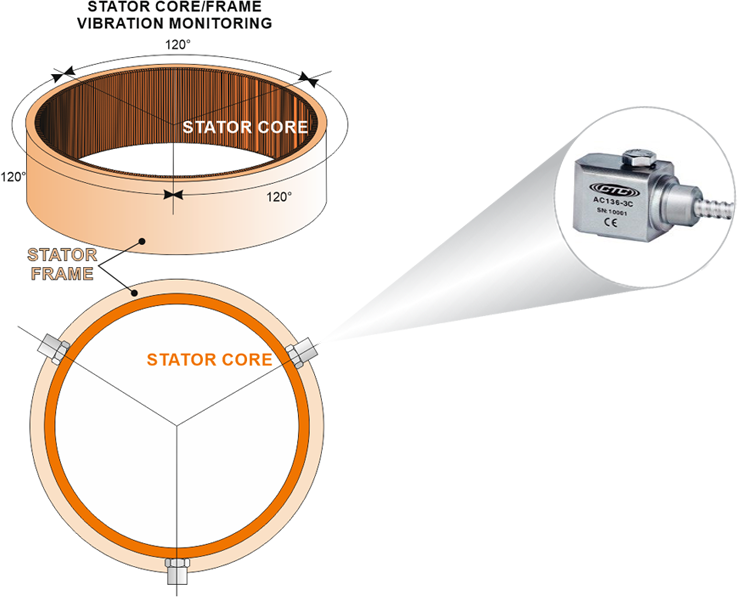

Stator core vibrations measurements are conducted using accelerometers or velocity meters positioned around the stator core, typically in radial directions on each segment.

Faults and conditions detected

Loose stator core (or segment joints)

Stator stiffness change in operation

Typical configuration

Accelerometers positioned around stator core (typically 3-6 sensors per unit)

CoDiS RT – on-line monitoring and protection instrument

CoDiS DM – on-line and off-line diagnostic software

On-line instrument

- CoDiS RT - Real time Protection unit

Diagnostic Modules

- CoDiS DM - Diagnostic Monitoring

END-WINDING

Stator end winding vibrations measurements are conducted using fiber optic accelerometers positioned around the stator core, typically in radial (also tangential) directions on end winding. Bump test is recommended to identify the best sensors location

Faults and conditions detected

Looseness of the end-winding support and tie structure due to mechanical aging and thermal expansion

Resonance conditions close to the primary mechanical forces of rotational frequency and twice the AC line frequency

Relative motion between one component and another which can abrade the high voltage insulation on the coils

Typical configuration

EVAII positioned around stator on end windings (typically 3-6/12 sensors per unit)

CoDiS RT – on-line monitoring and protection instrument

CoDiS DM – on-line and off-line diagnostic software

On-line Instrument

- CoDiS RT - Real time Protection unit

Diagnostic Modules

- CoDiS DM - Diagnostic Monitoring