CoDiS DM

On-Line Analysis and Diagnostic Software

CoDiS DM

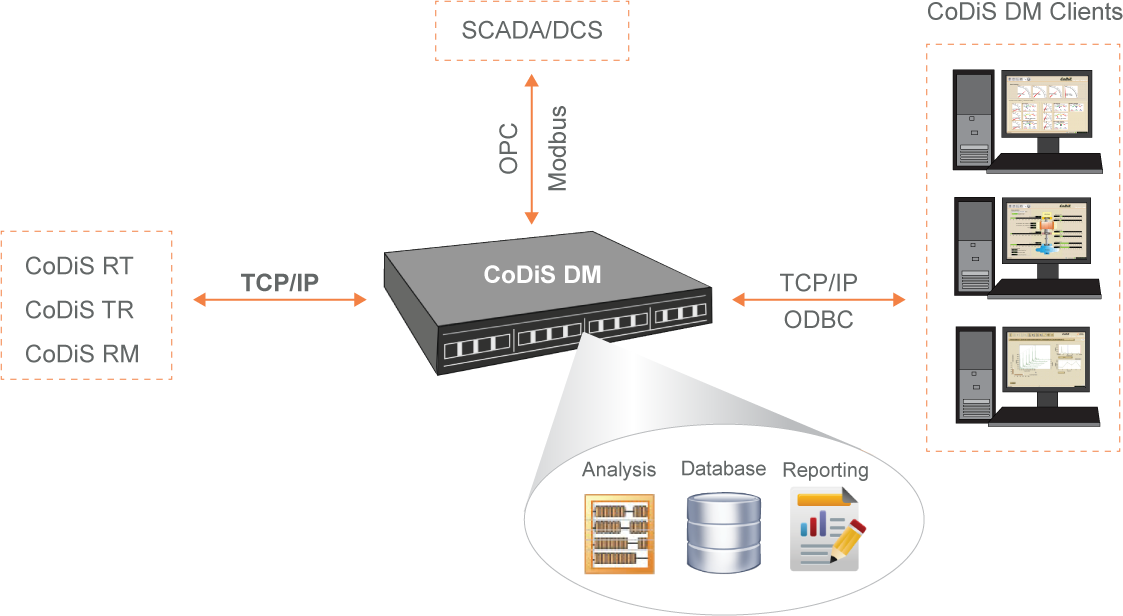

"CoDiS DM" is diagnostic platform and is used to create history database of all measured values and created events.

The system creates a database of each measured signal continuously while in operation constantly obtaining data from all CoDiS unit. Diagnostic monitoring module CoDiS DM is used for predictive maintenance, to detect permanent changes in machine performance and to track the condition changes in early phase.

Diagnostic monitoring provides continuous on-line data analysis, database recording and is responsible for data distribution to client users. Each event is archived and user has capability to track all the changes and apply diagnostic tools to extract the essential information and highlight the problem.

CoDiS DM tasks

Receives the Condition Vectors from CoDiS modules and performs history data storage and event recording in MySQL database

Evaluates the operating conditions and stores the data accordingly

Receives Alarm notification from CoDiS modules

Communicates with SCADA or DCS via OPC

Performs the time synchronization of CoDiS modules

Standard data analysis tools

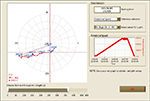

Bode plot, Nyquist plot

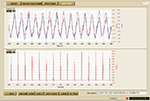

2D and 3D orbit analysis

2D and 3D shaft centerline

Run Out Compensation

Air Gap polar plot and stator geometry

Magnetic field pole profile

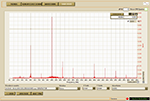

FFT spectrum, CPB spectrum

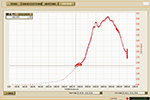

Waterfall spectrum

Expert data analysis tools

Critical speed identification

Statistical analysis of machine operation

Torsion vibrations identification