Services

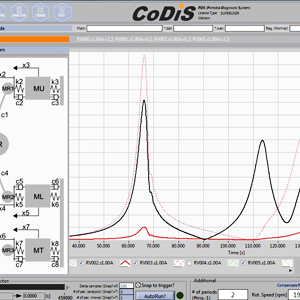

Machine condition measurements & diagnostics

Onsite measurements (data collection); vibrations, air gap, magnetic flux

Preliminary report – on site machine condition assessment

Detailed machine condition report with recommendations for repairs

On site balancing

Veski offers premium quality machine diagnostics

Root cause analysis

& problem solving

Root cause analysis

Solution proposal

Assistance in problem solving

We can help in machine health assessment and repair process

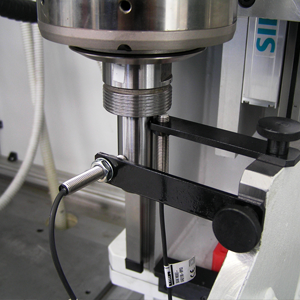

Onsite services

Sensor and instrument installation (supervision) and wiring

Software installation and setup

Communication setup

Alarm setup

Veski offers installation, installation supervision and commissioning services for various types of sensors and instruments

Math simulations

& modeling

Machine dynamics modeling

Simulation of various faults and conditions

Machine stiffness and critical speed identification (based on real vibration measurements in combination with machine model)

Our engineering team is capable of simulating your machine problems and set a footprint for condition monitoring

Custom tailored Test

& Measurement

Project and system design

Acquisition assembly of all necessary components (sensors, signal conditioning)

Design of software custom tailored to customer needs

Our team has successfully deployed custom tailored Test and Measurement stands for various factories and test labs.

Training

For more details – Academy

Veski team of experts can offer a comprehensive training as a part of our Veski Monitoring Academy program