Air gap monitoring

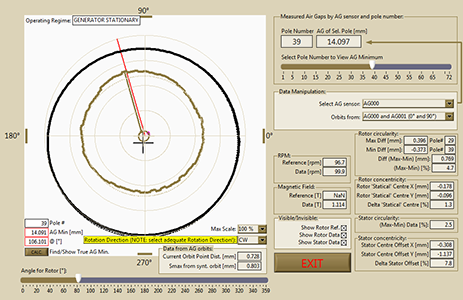

Air gap is the distance between the rotor outside and the stator inside diameter. Air gap monitoring of hydro generators, motors and gearless mill drives is important because the stator and the rotor geometry can be quite flexible, and their shape and location are significantly influenced by operating conditions (eg. centrifugal and magnetic forces, thermal effects and structure stiffness failures).

The fact that generated energy is transferred from rotor to stator through air gap, makes reliable identification of conditions in the air gap one of most important tasks in machine behaviour control.

Faults detected

Rotor pole profile/rotor geometry problems

Stator and rotor shape and eccentricity problems

Rotor vibrodynamic problems

Pole movement detection

Stator and rotor rub prevention

Typical configuration

Capacitive Gap Sensors around stator circumference

CoDiS RT – On-line monitoring and protection instrument

CoDiS DM – On-line and off-line diagnostic software

Sensors

- Capacitive Gap Sensor

On-line Instrument

- CoDiS RT - Real time Protection unit

Diagnostic Modules

- CoDiS DM - Diagnostic Monitoring